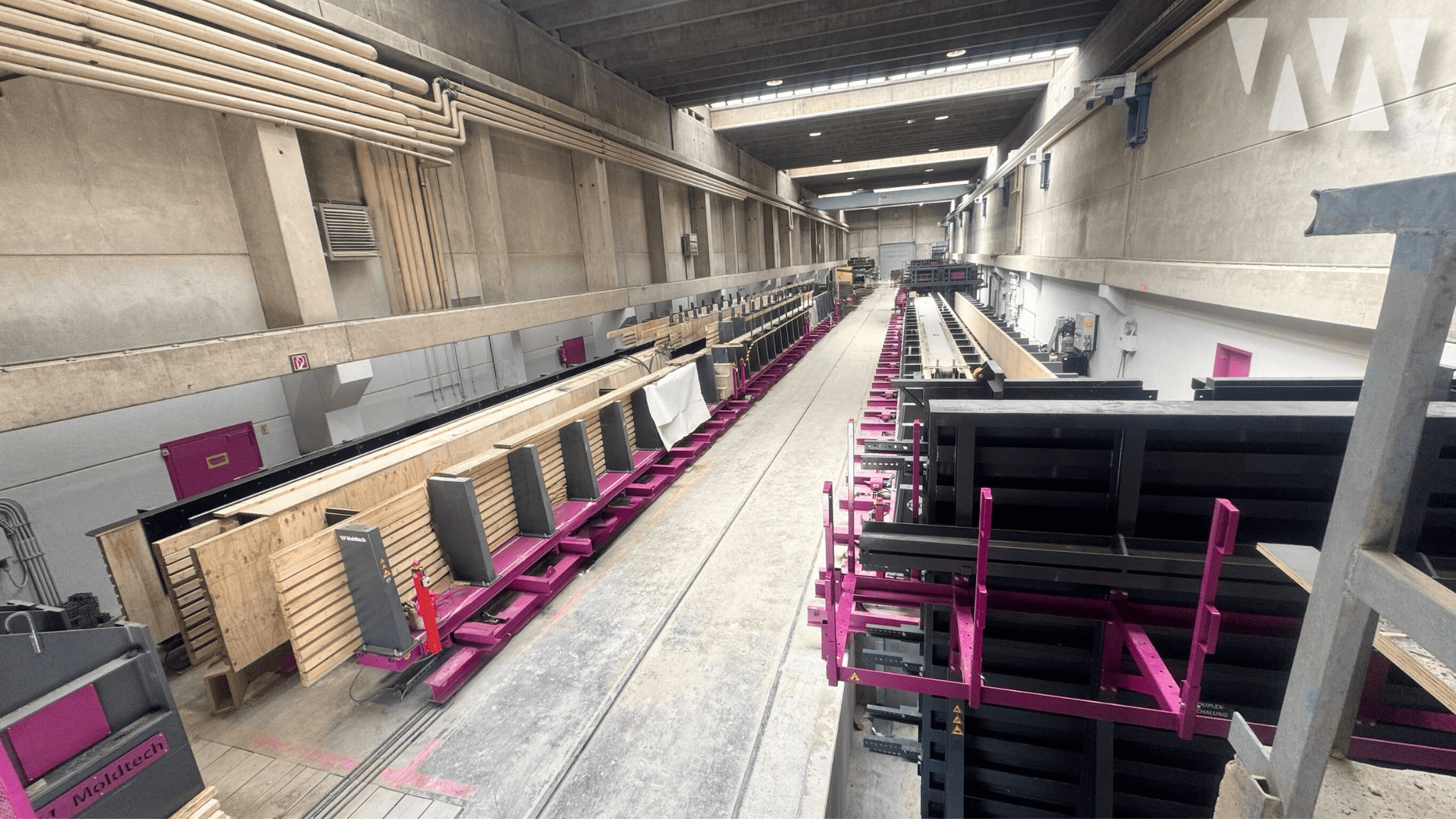

Moldtech continues to strengthen its international presence with a new project in Germany, one of Europe’s most demanding markets for precast, especially in the industrial sector. This new milestone consolidates our ability to adapt to local regulations, high quality standards and specific customer needs, offering complete technical solutions for the industrial production of concrete structural elements.

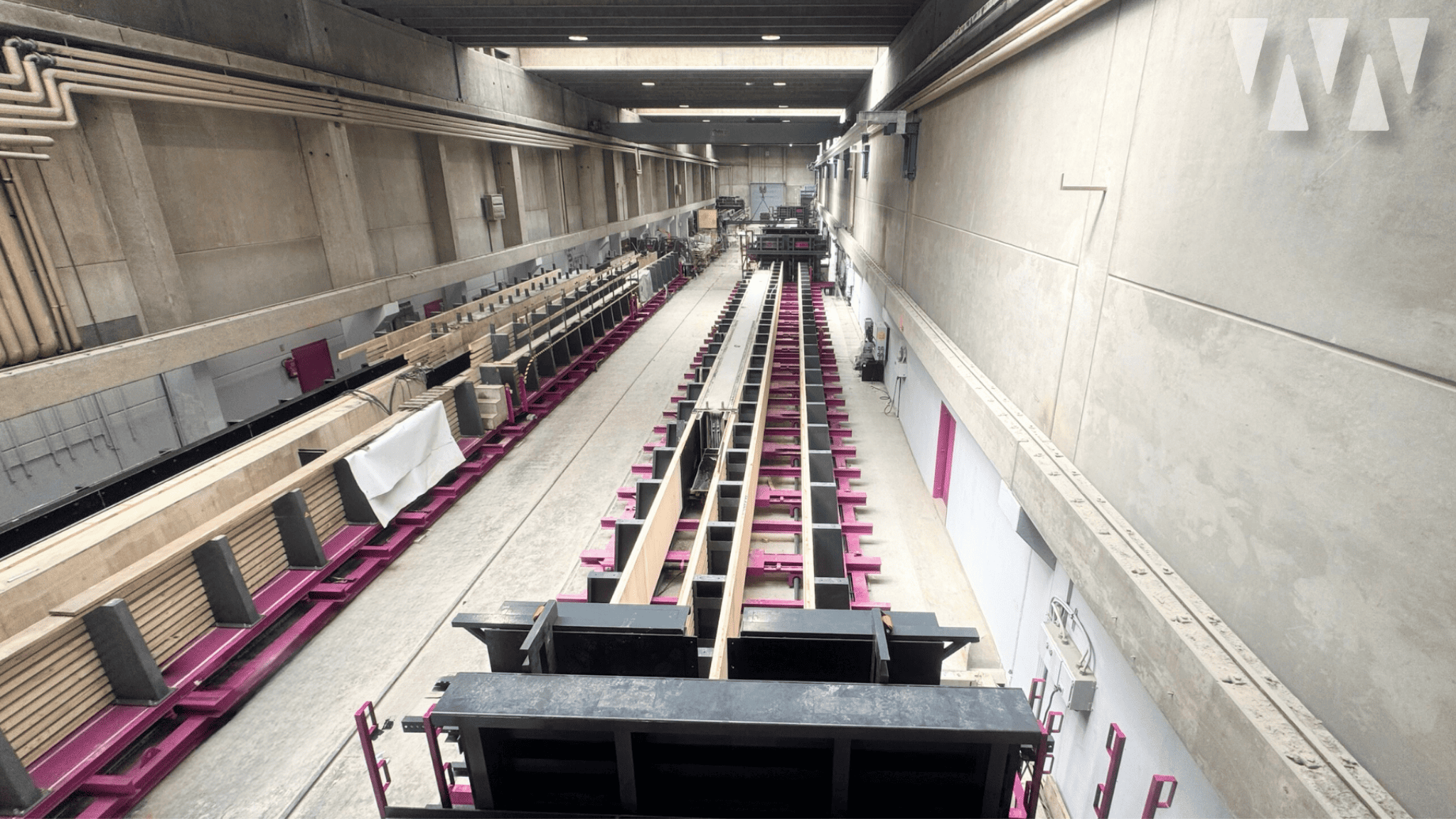

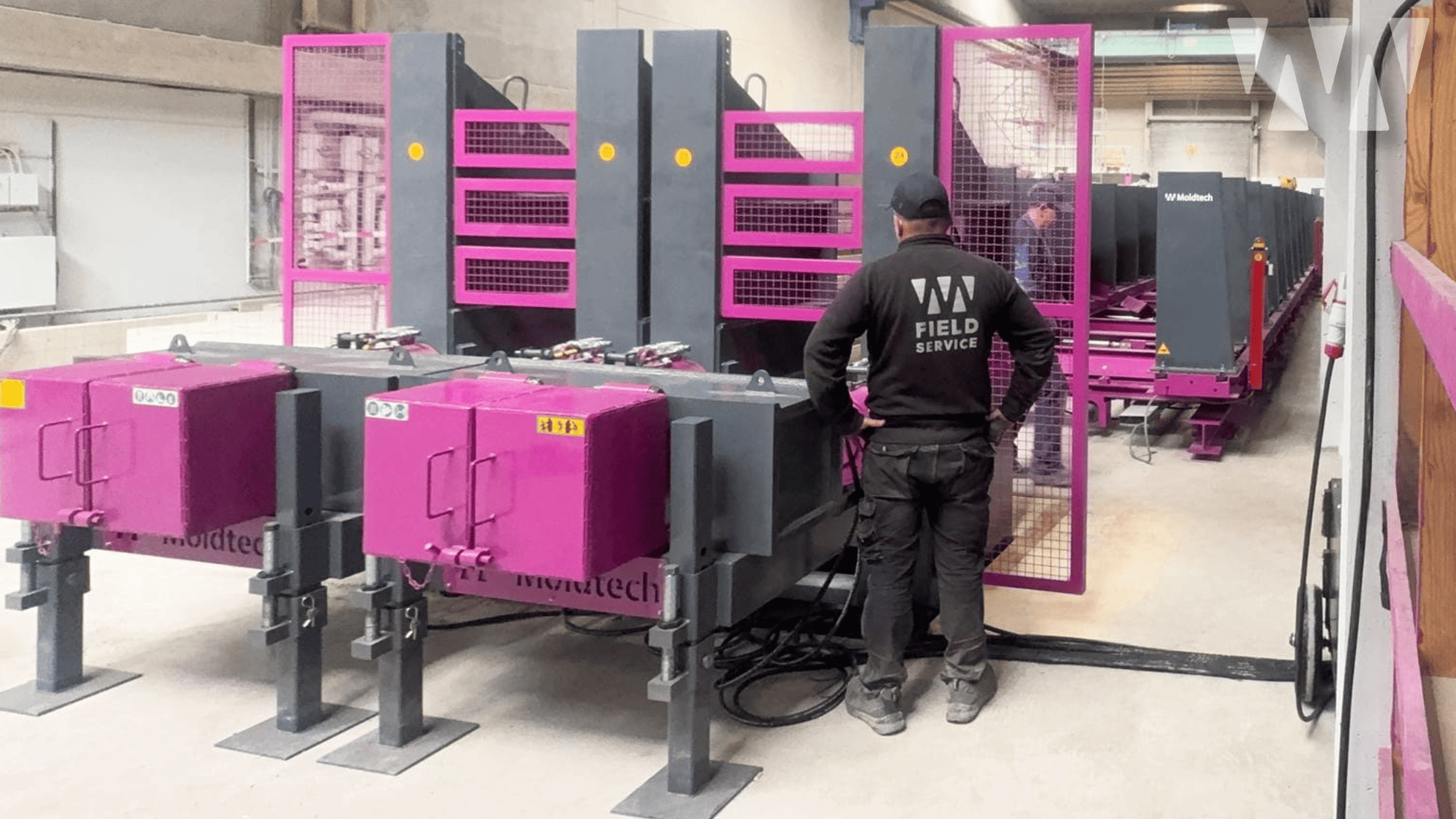

On this occasion, the supply includes an advanced set of moulds designed to maximize productivity and versatility in a precast plant: a double mould for the production of prestressed beams with a length of 34.5 m, and two hydraulic moulds for columns with footings capable of manufacturing different types of column sections.

Cutting-edge technology for large-format beams

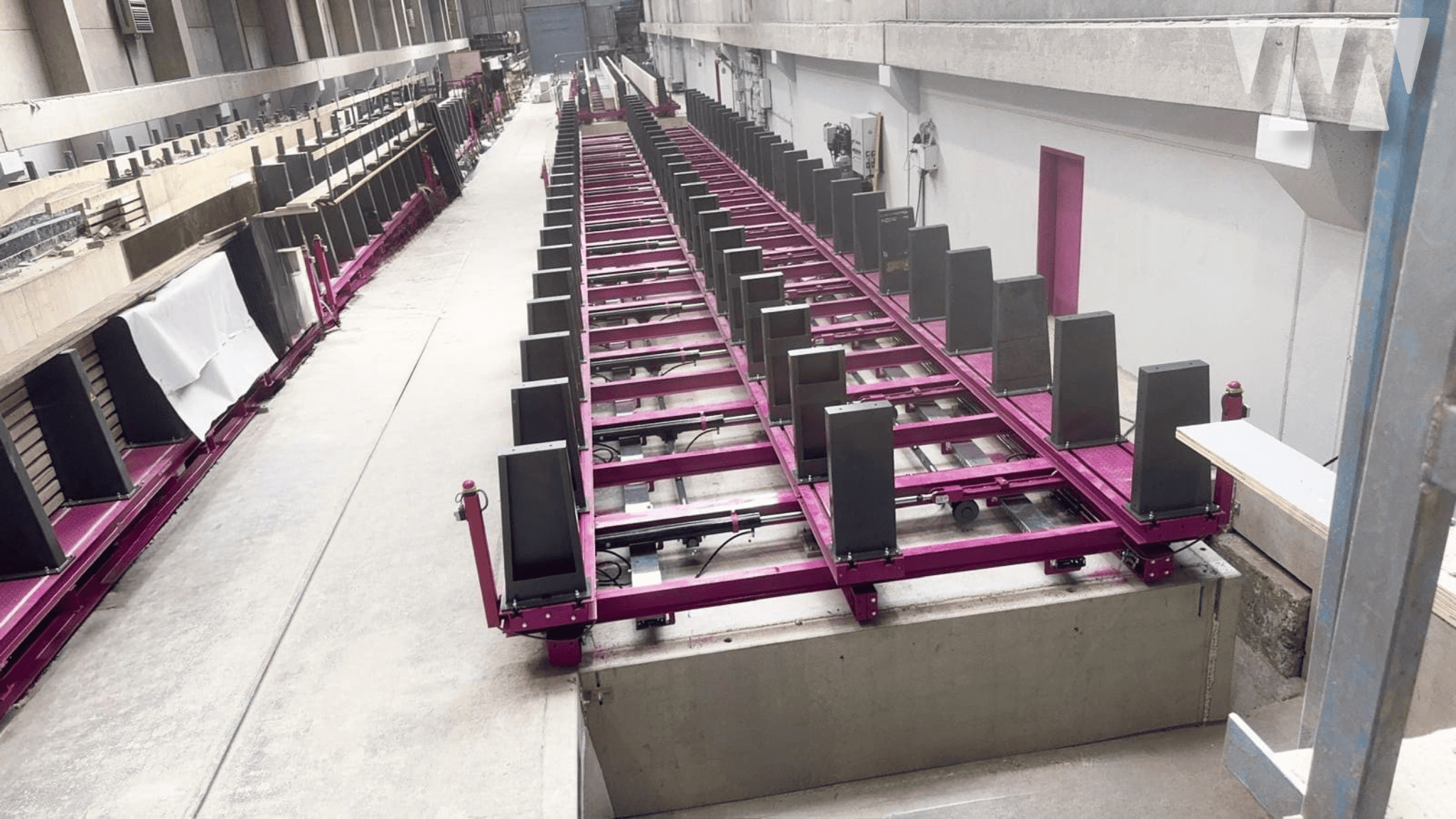

The double mould for prestressed beams allows several elements to be manufactured simultaneously, with sections varying between 280 mm and 1100 mm in width and heights of up to 1200 mm, which can be extended to 1800 mm thanks to its supplement system. Its modular design, combined with automated hydraulic opening, ensures faster, safer and more adaptable production cycles.

Includes:

- Active and passive stressing heads

- The base divided into different modules

- Adjustable supplements for different positions, allowing great flexibility for the customer

- Metal surface compatible with wooden planks

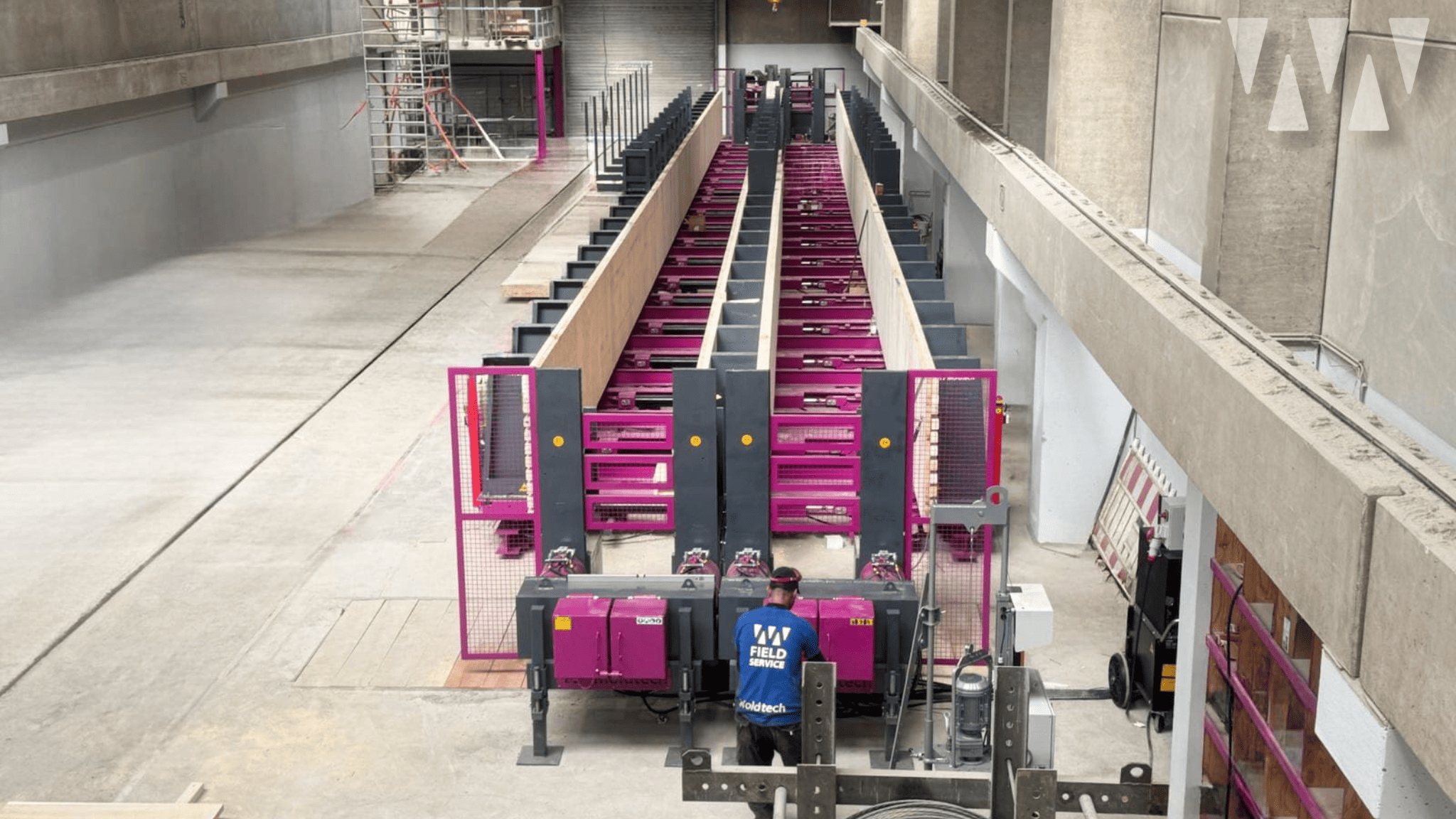

In addition, it includes a complete prestressing system consisting of:

- Hydraulic power unit for moving the outer sides

- Relaxation unit for controlled tension release of the prestressed strands

- Prestressing equipment up to 400 tonnes

- Two strands decoilers

Mould for columns with footing: versatility and precision

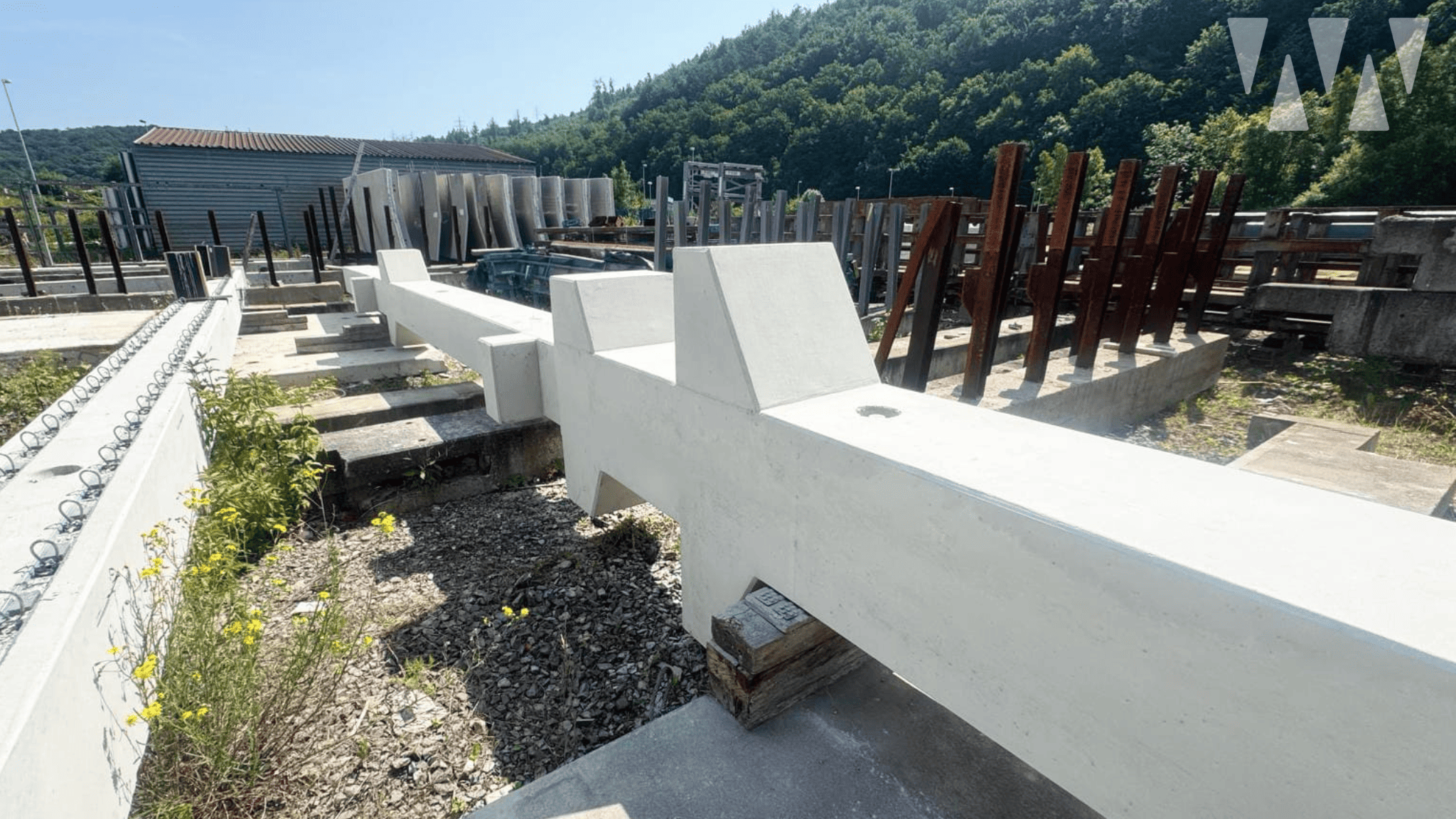

The supply is completed with two double hydraulic moulds for the production of columns with base plates, capable of simultaneously producing several columns of different sections. The standard configuration includes two outer sides, each with a hydraulic opening and closing system, as well as a common central panel, allowing the manufacture of columns with corbels on up to three sides. This equipment also includes a variant with a double central panel to allow corbels production on all four sides.

These moulds are designed to facilitate adaptation to different geometries thanks to:

- Hydraulic opening by means of synchronized cylinders

- Interchangeable and height-adjustable bottoms

- Hydraulic height adjustment in advanced versions

To increase the quality and productivity of this equipment, the moulds can incorporate:

- Electric or pneumatic vibration system to improve the finish and compaction of the concrete

- Heating system using finned pipes to accelerate the curing of the concrete

- The corbels system consists of specific boxes and replaceable formwork, allowing the position of the corbel to be varied or completely removed depending on the project. This provides the customer with great flexibility and versatility when producing different column sections.

Global presence and adaptability

This project in Germany not only strengthens our presence in the German market, but also demonstrates Moldtech‘s ability to operate successfully anywhere in the world. Our experience allows us to offer tailor-made solutions both in mature markets such as Germany, France, and in developing markets in Asia, Africa and Latin America.

Regardless of the destination, our solutions meet the highest international standards in terms of safety, structural quality and operational efficiency. We design each piece of equipment to suit the environment, regulations and expectations of each customer, regardless of their location or level of industrialization.

At Moldtech, we don’t just manufacture moulds: we develop complete solutions for precast construction, aligned with real market demands and with a vision for the future.

➡️ If you would like to know how we can help you take your prefabrication plant to the next level, contact our technical team and discover everything Moldtech has to offer.