This machine belongs to the so-called auxiliary equipment category which does not produce any concrete elements itself but fulfil an absolutely critical role in making certain operational tasks easier at the precast factory.

In this sense the turners can have a great impact when the casting position of the precast element is not the same as the final position the element will be placed at the job site. In the precast industry some products have to be casted in an upside-down position for a variety of reasons like to obtain a better quality finish of the casted element or because in the upside- down position the pouring process can be accomplished easier and faster.

Turners are especially of great help in the case the size of the casted element is large and its weight very heavy. In those cases the tuners offer a safe alternative in comparison to any other turning method.

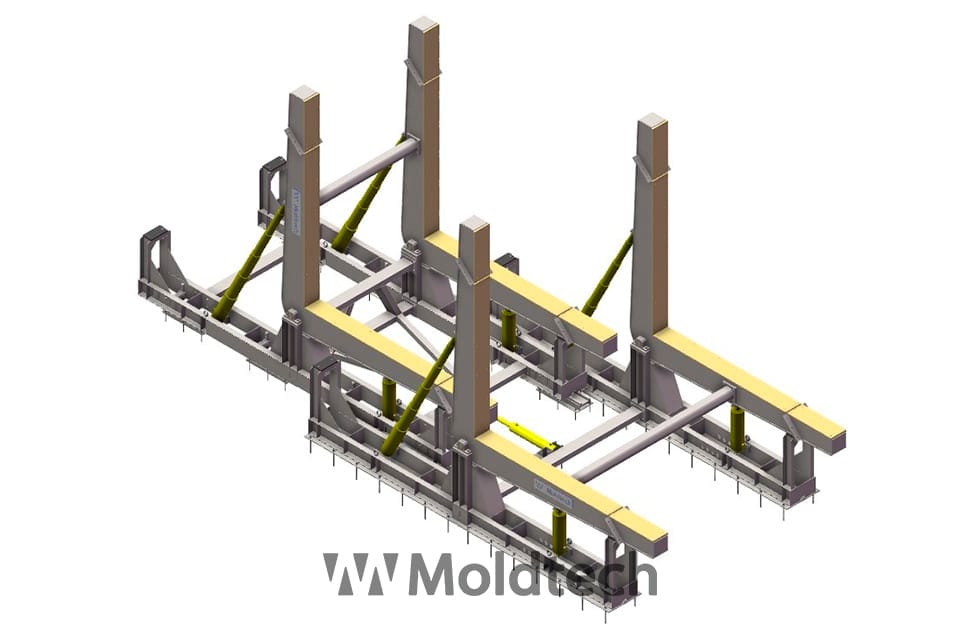

The turner for Malaysia is prepared to handle 3D elements in a size range from 6 x3 x 3 meters up to 9 x 4 x 4 meters and a total weight of 40 tons. The adjustment for the sizes is achieved by using a hydraulic system which adjust the distance between the forks.

Vídeo of testing 180º turner.

|