After intense prospecting of the German market and after years of commercial effort, we have managed to consolidate ourselves in a highly competitive and demanding environment, which demonstrates our skills and the high quality of our products in this important region of Europe.

Moldtech supplies its first moulds To Germany, combining versatility and performance for the manufacture of concrete panels in the residential sector.

Our client’s construction projects are under pressure of high quality, deadlines and costs. Our client has been producing, delivering and assembling precast structural elements for its customers in Germany for over 50 years. Focusing on sustainable solutions, all of its precast plants use concrete recipes based on low CO2 emissions, thus actively contributing to the conservation of resources.

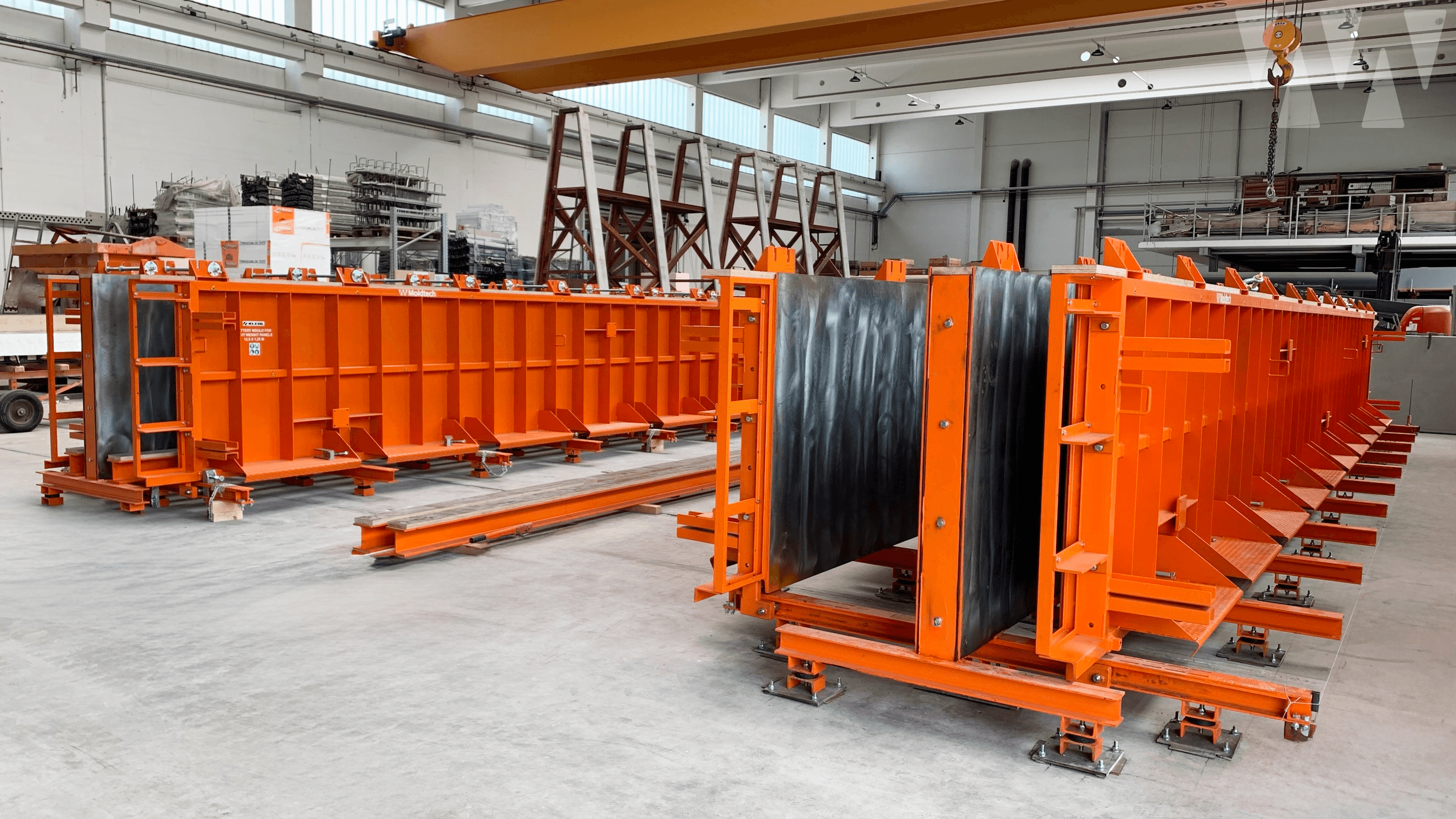

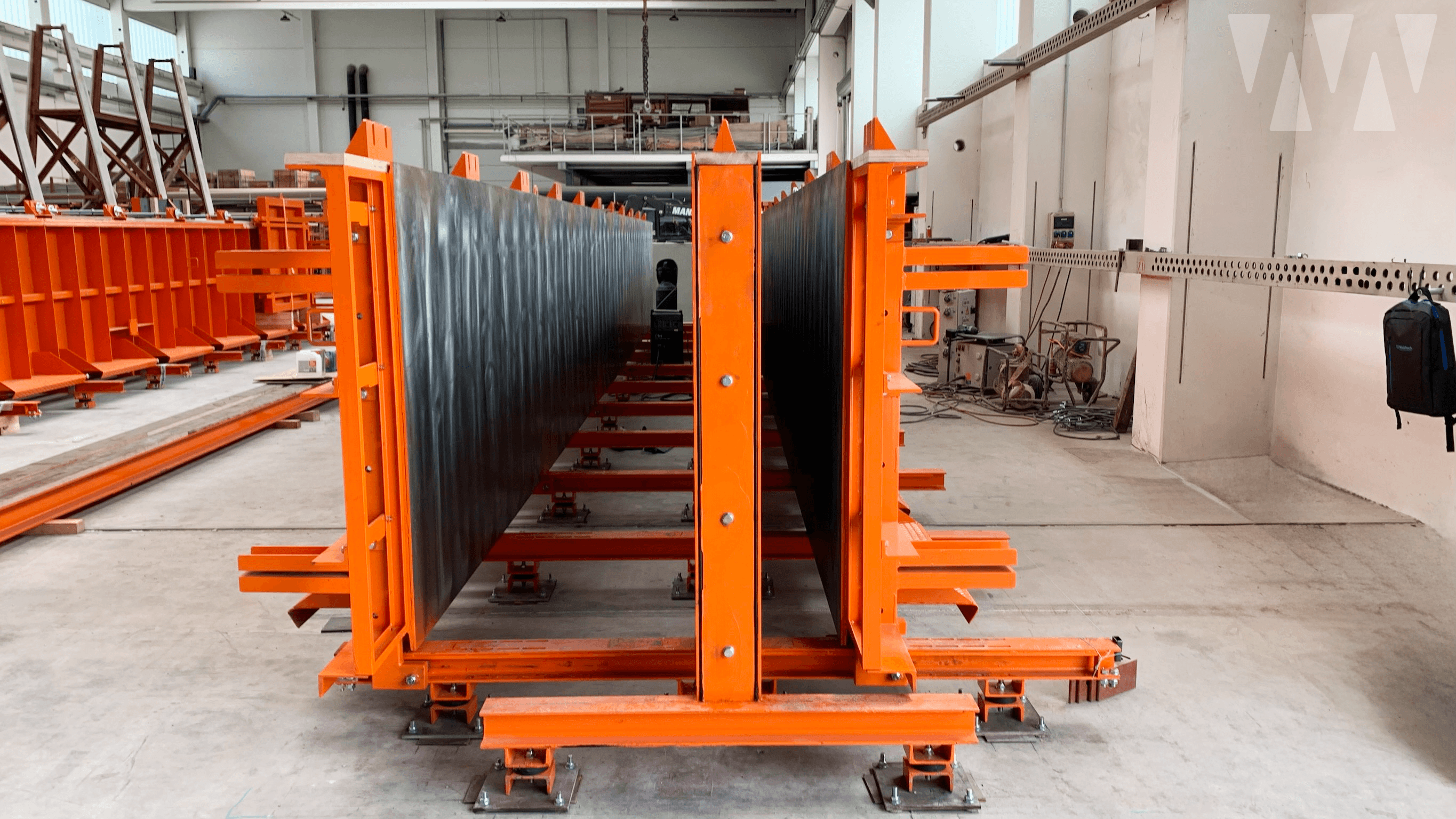

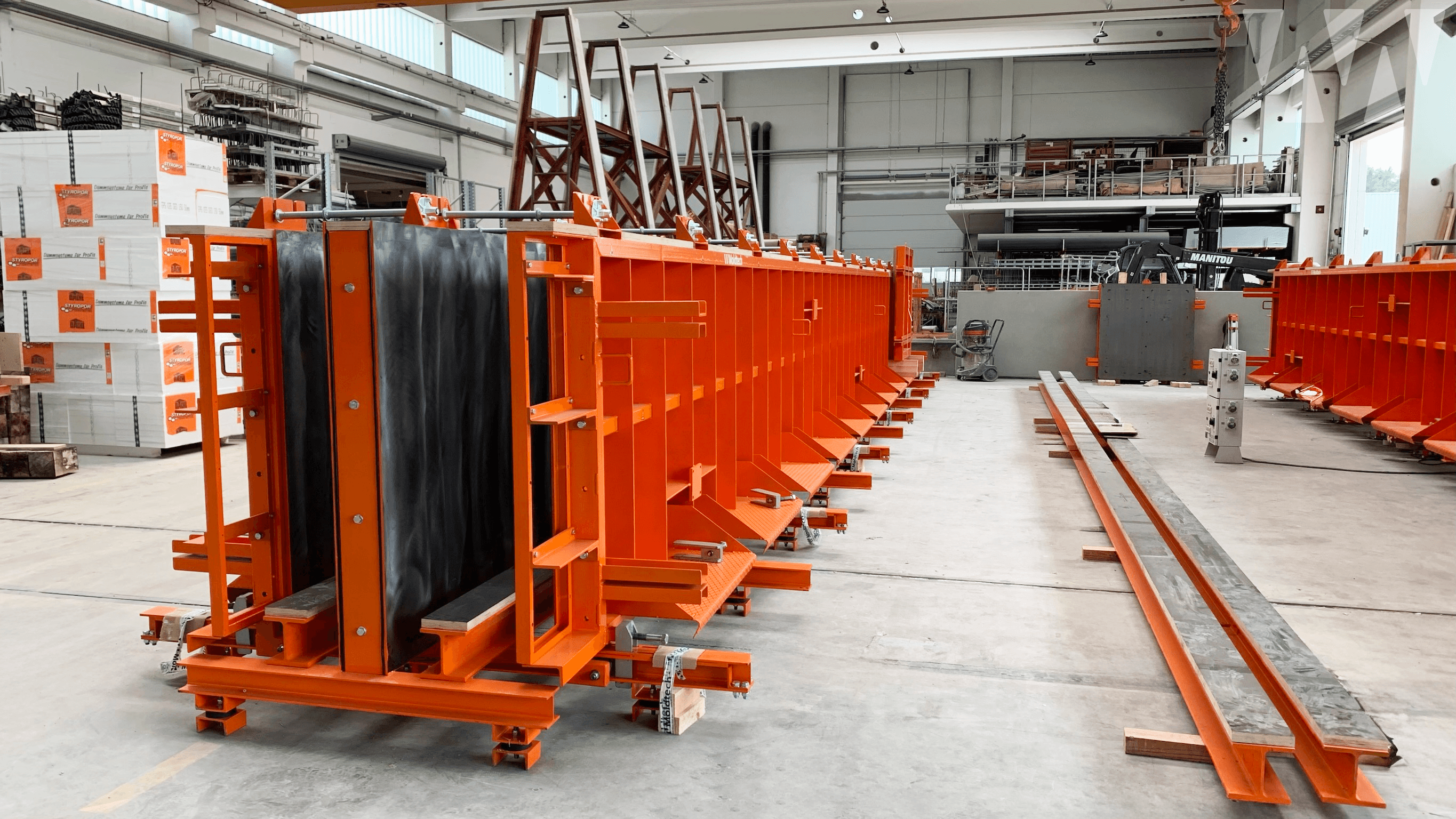

A 13.5 x 1.25 m manual battery mould with 2 casting slots is supplied, designed to simultaneously manufacture 2 precast concrete elements of variable section, and is composed of a frame and a central fixed panel, mobile side panels, interchangeable bottom holders and slits at their ends that give the shape to the element to be manufactured.

Moldtech’s manual battery mould will not only be used for manufacturing concrete panels, but is also designed to produce columns, expanding its versatility and application in residential projects.

Precast columns are fundamental structural elements in the construction of buildings, since they support vertical loads and distribute the weight of the structure towards the foundations. With this manual battery mould, it is possible to manufacture reinforced columns with precision and efficiency, resulting in high-quality components that meet strict structural requirements.

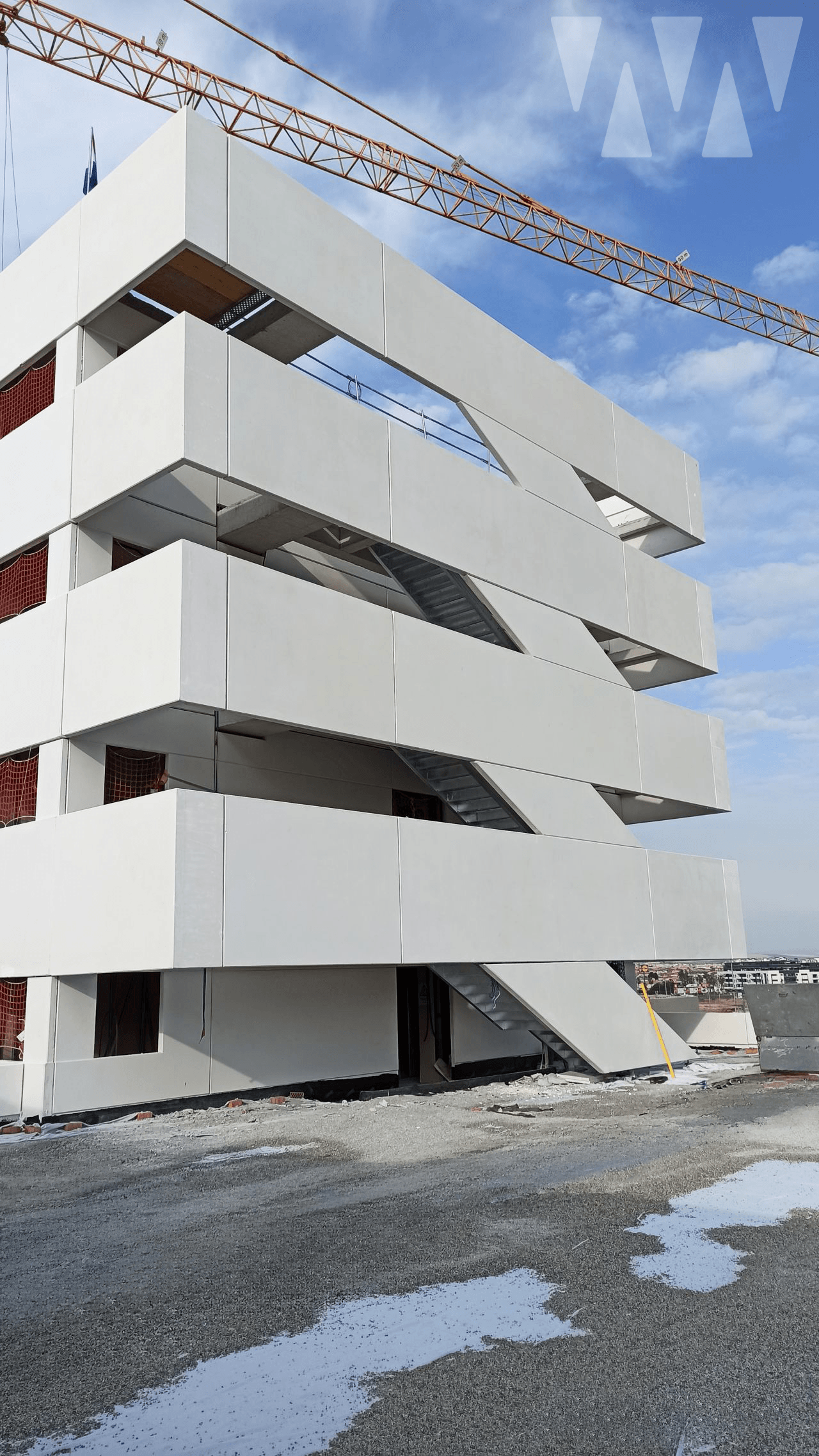

In addition to its application in columns manufacturing, these moulds allow for the creation of other elements such as balconies, fence roof and other structural components that are essential in residential design. Balconies, for example, not only add aesthetic and functional value to a building, but also require precision in their manufacturing to ensure safety and stability.

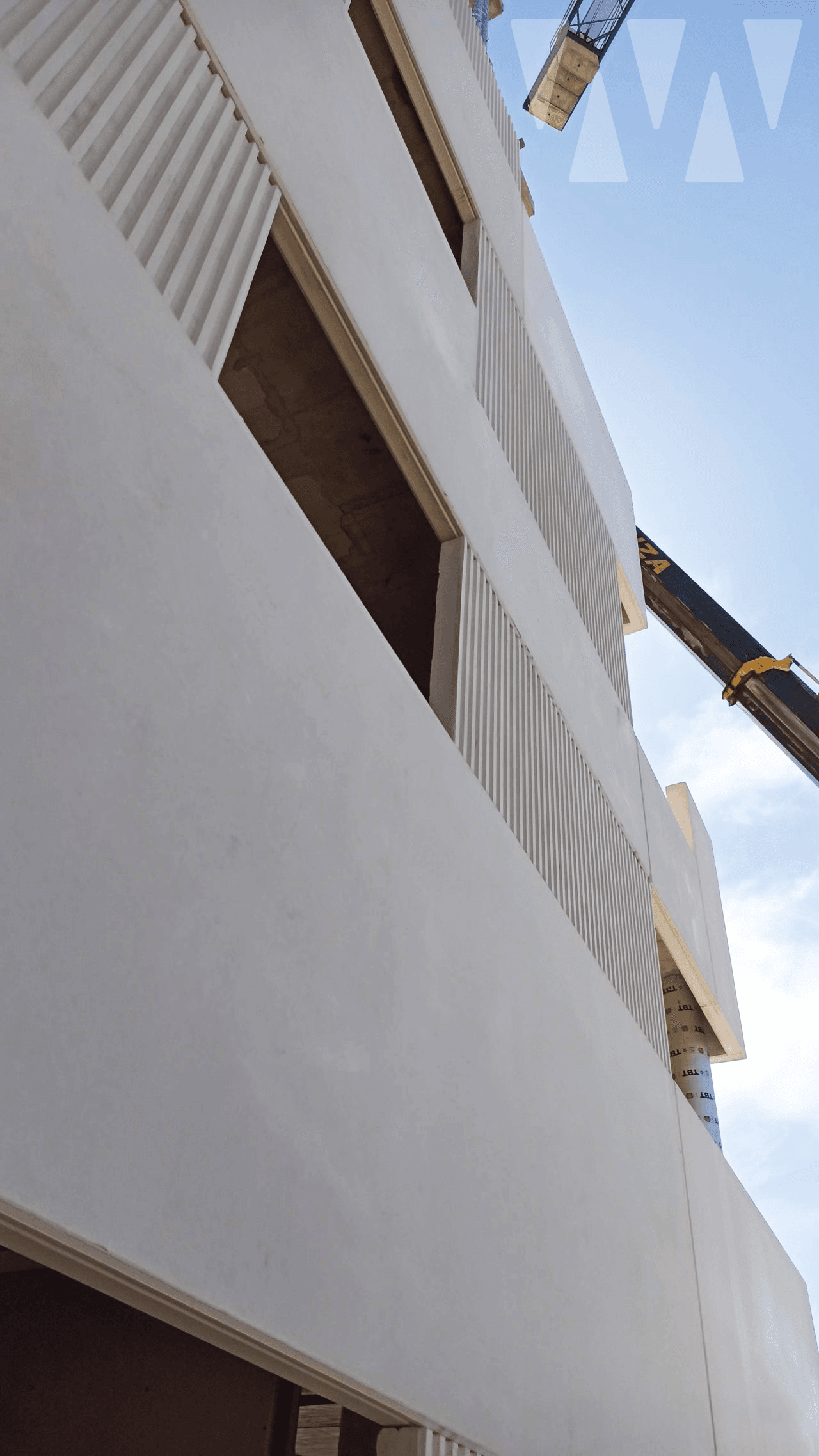

Precast concrete panels produced with manual battery moulds and intended for the residential sector are an increasingly popular solution in modern construction. These elements offer a number of both aesthetic and functional benefits, making them an attractive option for developers, architects and builders in residential projects.

In terms of durability, they are extremely resistant to adverse weather conditions such as humidity, wind, heat and cold, which contributes to reducing long-term maintenance costs. Likewise, they maintain their appearance and functionality over time, guaranteeing longevity.

Finally, the thermal and acoustic insulation properties of these panels significantly improve the interior comfort of homes, helping to control temperature and reduce exterior noise, which is essential for energy efficiency and the well-being of the inhabitants.

As the residential sector continues to evolve, concrete is establishing itself as the preferred option for projects that seek to combine development, security and energy efficiency. With solutions like those from Moldtech, concrete is increasingly positioned as the fundamental pillar of the construction of the future.